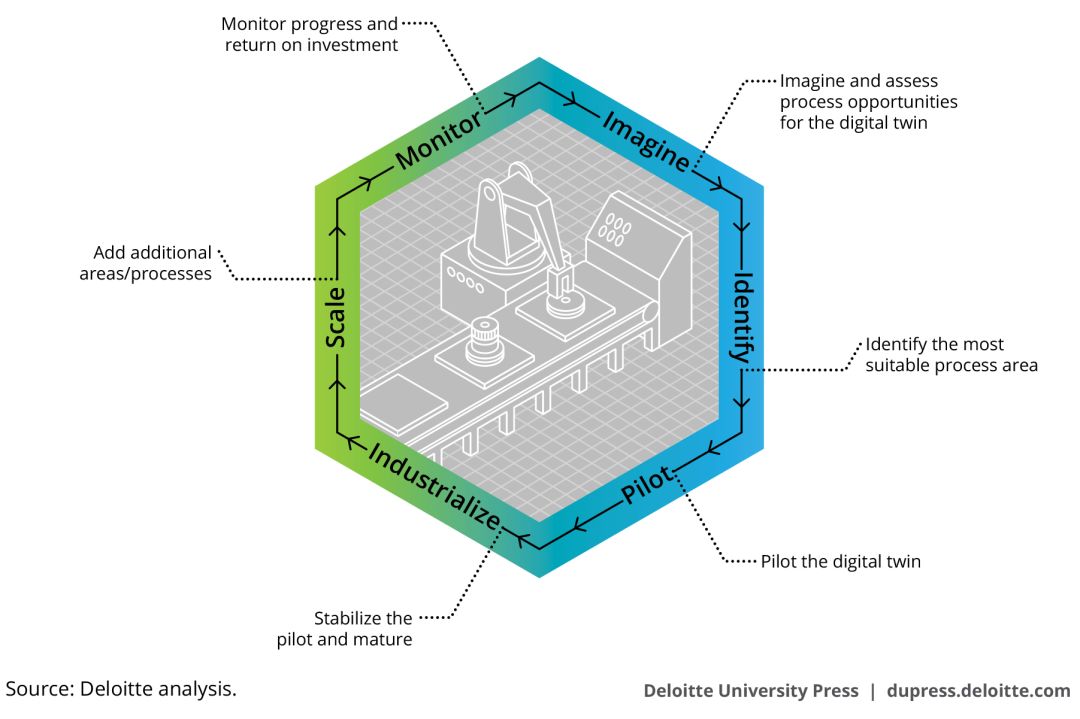

After the shortlist of scenarios is created, each scenario would be assessed to identify pieces of the process that can provide quick wins by using a digital twin. We encourage a focused ideation session with members of operational, business, and technical leadership for expediting the assessment.

Identify the process. The next step would be to identify the pilot digital twin configuration that is both of the highest possible value and has the best chance of being successful. Consider operational, business, and organizational change management factors in identifying which configurations could be best candidates for the pilot. Focus on areas that have potential to scale across equipment, sites, or technologies.

Pilot a program. Consider moving quickly into a pilot program using iterative and agile cycles to accelerate learning, manage risk proactively, and maximize return on initial investments. As you move through the pilot, the implementation team should support adaptability and an open mind-set—at any time of your journey, maintain an open and agnostic ecosystem that would allow adaptability and integration with new data (structured and unstructured) and leverage new technologies or partners.

Industrialize the process. Once success is shown in the field, you can industrialize the digital twin development and deployment process using established tools, techniques, and playbooks. This may include moving from a more siloed implementation to integration into the enterprise, implementation of a data lake, performance and throughput enhancements, improved governance and data standards, and implementation of organizational changes to support the digital twin.

Scale the twin. Once successful, it can be important to identify opportunities to scale the digital twin. Target adjacent processes and processes that have interconnections with the pilot. Use the lessons learned from the pilot and the tools, techniques, and playbooks developed during the pilot to scale expeditiously.

Monitor and measure. Solutions should be monitored to objectively measure the value delivered through the digital twin. Identify whether there were tangible benefits in cycle time, yield throughput, quality, utilization, incidents, and cost per item, among others. Make changes to digital twin processes iteratively, and observe results to identify the best possible configuration.

Most importantly, this is not a project that should typically end once a benefit is identified, implemented, and measured. To continually differentiate in the market place, companies should plan time to move through the cycle again in new areas of the business over time.

All in all, true success in achieving early milestones on a digital twin journey will likely rely on an ability to grow and sustain the digital twin initiative in a fashion that can demonstrate increasing value for the enterprise over time. To help ensure such an outcome, one may need to integrate digital technologies and the digital twin into the complete organizational structure—from R&D to sales—continuously leveraging digital twin insights to change how the company conducts business, makes decisions, and creates new revenue streams.

Related articles: